Industrial Silica Sand (SA)

We are processing raw silica sand in multi-stage including washing, attrition, drying and sieving to get well graded high purity products of ....

Silica Flour (SA)

Our processed silica sand feed in a rotary ball mill connected with air classifiers to produce various sizes of silica flour ranging from 10 to 150 microns.

Oil & Gas Sand

We invested in State-of-the-Art Technology to produce well graded natural proppant (Frac Sand and Gravel Pack Sand) according to API 19C standards, that use to stimulate oil well production.

Filtration Sand & Gravel

We are producing high quality filtration sand and gravel, with high silica content ....

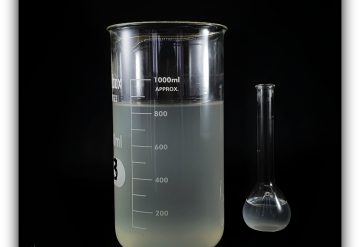

Sodium Silicate

The State-of-the-Art Technology is used to produce two types of sodium silicate Alkaline and Neutral. A premium product in solid and liquid forms with maximum metal oxides impurities 0.5% is produced.

Hydrochloric acid (HCl 33%)

Hydrogen chloride is produced by direct synthesis between chlorine and hydrogen The synthesis is carried out by combustion of chlorine with hydrogen followed by absorption by water, the temperature of the finished product reaches 30°C

Sodium Hydroxyde (NaOH 32% and 45%)

Sodium hydroxide NaOH, in other words caustic soda, is produced by electrolysis of a solution of sodium chloride NaCl, (100%).

Sodium Hypochlorite (NaOCl 48°)

The solution of sodium hypochlorite (NaOCl) is made by a neutralization reaction of chlorine (in the gaseous state) in dilute caustic soda. The chlorine and soda used are obtained by electrolysis of brine (NaCl).

Liquid Chloride (Cl2)

liquid chlorine is produced by adding gaseous chlorine (97%) which is produced by the electrolysis of brine on sulfuric acid H2SO4 in order to absorb chlorine water, then it is compressed by a compressor and cooled using a heat exchanger.

Ferric Chloride (FeCl3)

Ferric chloride which is obtained from a reaction of iron with chlorine in the presence of water:

Calcium Chloride (CaCl2)

A new calcium chloride CaCl2 production plant is under construction and will start production from June 2023.

Industrial Silica Sand (DZ)

We are processing raw silica sand in multi-stage including washing, attrition, drying and sieving to get well graded high purity products of ...

Silica Flour (DZ)

Our processed silica sand feed in a rotary ball mill connected with air classifiers to produce various sizes of silica flour ranging from 10 to 150 microns.